The Future of “Smart” Packaging: Integrating Intelligence into Flexible Films

For decades, the primary role of flexible packaging has been passive protection: providing a barrier against moisture, oxygen, and physical damage. However, the industry is undergoing a rapid evolution. Driven by demands for enhanced food safety, stricter pharmaceutical regulations, and a better consumer experience, packaging is transitioning from a passive container to an active participant.

Welcome to the era of “Smart Packaging”—the incorporation of freshness, temperature, and tamper-evidence indicators directly into flexible film structures. While the marketing benefits are clear, engineering these intelligent structures presents complex challenges that require rigorous scientific validation.

Understanding the Smart Packaging Landscape

“Smart” packaging is generally divided into two categories: Active Packaging (which interacts with the product to extend shelf life, such as oxygen scavengers) and Intelligent Packaging (which communicates the condition of the packaged product).

For flexible film manufacturers and end-users, integrating intelligent indicators is becoming a key competitive advantage. The most common applications include:

- Freshness and Spoilage Indicators: These technologies detect chemical changes inside the package. For example, as meat or seafood begins to spoil, it releases specific volatile amines. Indicators embedded in the film matrix or applied as intelligent labels change color in response to these chemical shifts, alerting consumers and retailers before a health hazard occurs.

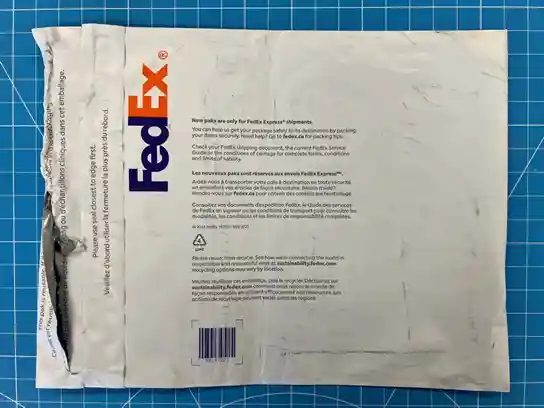

- Time-Temperature Indicators (TTIs): Critical for cold-chain logistics in the food and medical sectors. TTIs visually record a product’s temperature history, showing if a temperature-sensitive product (like a vaccine or dairy item) has been exposed to conditions outside its safe range, even if it has since been refrozen or cooled.

- Advanced Tamper-Evidence and Traceability: Beyond traditional tear-notches, modern intelligent films can incorporate printed electronics, RFID, or NFC (Near Field Communication) tags directly into the laminate layers. This ensures product authenticity, tracks the item through the supply chain, and provides irrefutable evidence of tampering.

The Engineering Challenge: Intelligence vs. Integrity

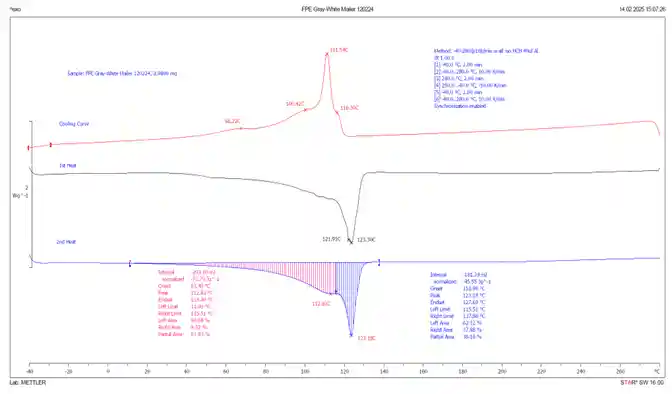

The concept of smart packaging is highly appealing, but the reality of manufacturing it is complex. You cannot simply introduce new chemical indicators, conductive inks, or foreign substrates into a flexible film without altering its fundamental properties.

This is where the engineering and testing phase becomes critical. When developing smart packaging, several risks must be mitigated:

- Barrier Compromise: Does the addition of an intelligent layer or printed sensor negatively impact the film’s Oxygen Transmission Rate (OTR) or Moisture Vapor Transmission Rate (MVTR)?

- Seal Strength Reduction: Contaminating the seal area with conductive inks or temperature-sensitive compounds can weaken heat seals, leading to premature failure and leaks.

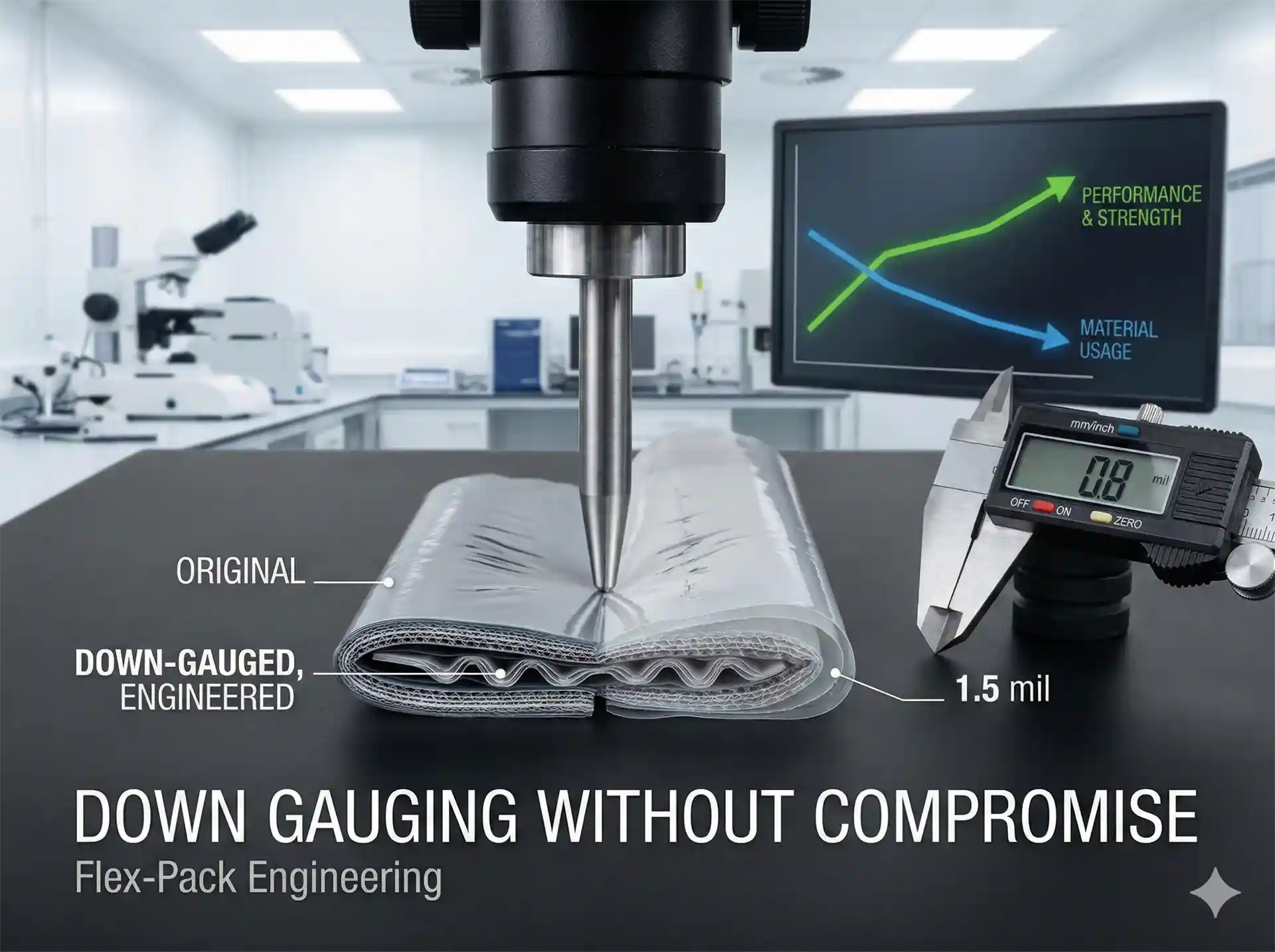

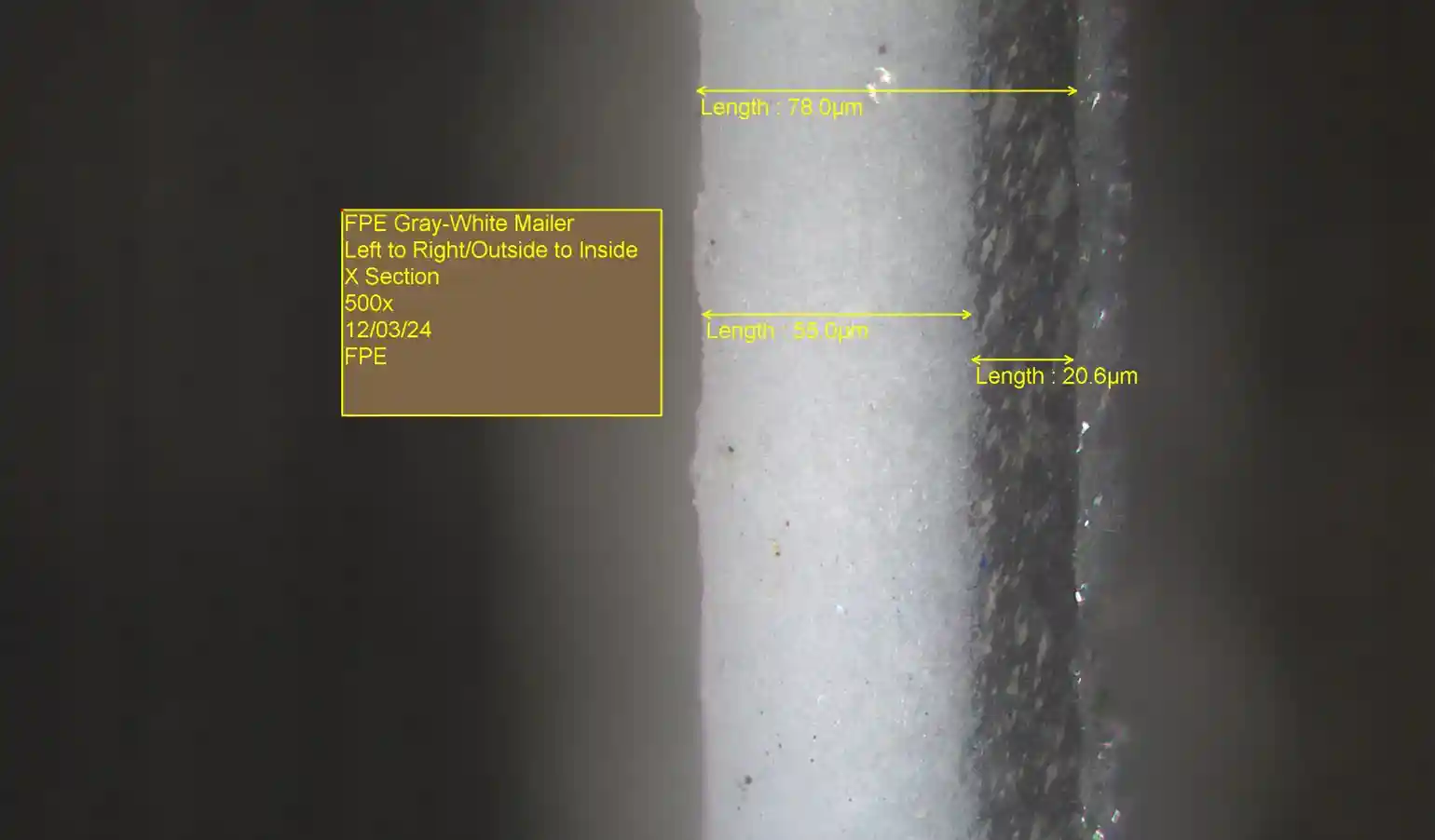

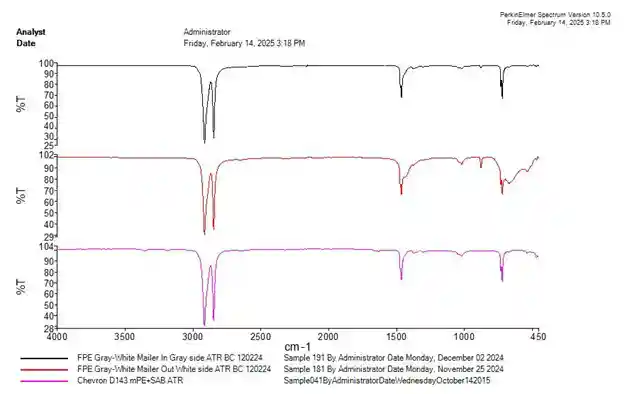

- Material Compatibility: How do these new components interact with the base polymers? Differential Scanning Calorimetry (DSC) testing is often required to ensure that the new materials do not disrupt the polymer’s crystalline structure or phase transitions.

- Migration Risks: Especially in food and pharmaceutical applications, rigorous testing is required to ensure that the active or intelligent compounds do not migrate through the film and contaminate the product.

The Need for Unbiased Validation

Innovating in the smart packaging space requires more than just a great idea; it requires empirical data. Before bringing a “smart” film to market, it must undergo a comprehensive suite of ASTM and ISO testing to establish its Fitness for Use (FFU).

Integrating intelligence into flexible packaging should not mean compromising on the primary goal: protecting the product. Through advanced compounding analysis and rigorous mechanical and analytical testing, these modern structures can be optimized for both intelligence and integrity.

How Flex-Pack Engineering Can Help

Navigating the complexities of smart packaging requires an expert partner. Flex-Pack Engineering provides the unbiased, third-party analytical and physical testing required to validate next-generation flexible films.

Whether you need to test the barrier properties of a new intelligent laminate, evaluate seal strength, or troubleshoot a compounding challenge, our laboratory is equipped to help you bring your smart packaging solutions to market safely and profitably.

Contact Flex-Pack Engineering today at 888-300-1482 to discuss your next packaging innovation.