Film, Compounding, and Flexible Packaging Consulting

Helping customers achieve their film, compounding and flexible packaging goals

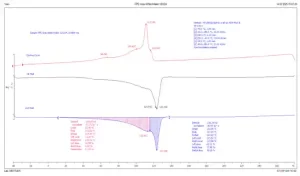

At Flex-Pack Engineering, Inc. we provide flexible packaging consulting that helps our customers not only improve existing manufacturing efficiencies, but also analyze and evaluate potential new market segment opportunities. Our process begins with understanding the application and desired outcome, understanding the context of what the customer wants to achieve, and then lab testing and lab result interpretations to explain results and make recommendations on how to achieve the desired results. With our nearly 30 year education in all facets of flexible packaging, once we understand what the customer has tried and what is not working, and the context of the application, we often can identify the problem and be ready with recommendations on how to proceed for a successful outcome.

Customers often reach out to Flex-Pack Engineering for flexible packaging consulting services with the desire to enter into a new market segment that appears lucrative, one for which it appears they can participate based on their experience, equipment, and capabilities. We will meet with the customer and discuss what packaging they are doing today, and what packaging they want to be doing tomorrow to enter into that new market segment. We will review equipment, quality systems, manufacturing capabilities, raw materials selection, and supply and distribution chains. We evaluate all facets of the initiative, not just technical but also business and economic concerns to help customers determine what they can do today, and what changes or investments are needed to enter the new market segment. Do you need to buy equipment, change systems, or modify what you have to make it suitable for what you want to do? And does it make sense to pursue the initiative or do you have to change so much and invest heavily that it disrupts what you are currently producing and adversely affects the existing manufacturing product lines.

At Flex-Pack Engineering, we can help you understand these dynamics and make a sound business decision. We can evaluate your existing equipment and determine which assets can be modified to run the new product line, and which cannot be modified or are needed to maintain existing product lines. If there are capacity concerns to run both existing and newer product lines, we can review design, screw configurations, system configurations, and control systems in order to improve the capacity of existing manufacturing assets.

Flex-Pack Engineering: Beyond Consulting, We Offer Turn-Key Solutions With Extensive Capabilities

One of the unique aspects of Flex-Pack Engineering is that we are not only consultants but can offer our customers an extensive array of flexible packaging capabilities. These capabilities include such activities as lab testing, proof of concept processing, small lab lines for compounding and film making, as well as printing and laminating. Through our extensive partner network, we have access to commercial assets that can handle most any size runs for toll compounding and commercial manufacturing.

Flex-Pack Engineering is ready to help you find the answers you need to achieve your desired goals. Ready to have a conversation? Give us a call at 888-300-1492 or contact us today!