Reverse Engineering Services for the Flexible Packaging Industry

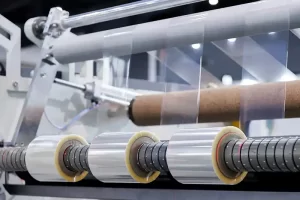

In the flexible packaging industry, reverse engineering services involve evaluating competitive samples that are available in the public domain or available commercially for packaging products. The process involves breaking those products down to understand how they are assembled and the types of materials that comprise those structures. At Flex-Pack Engineering based on our long history in the flexible packaging industry we can understand how those structures were made and what processes were used to create those structures.

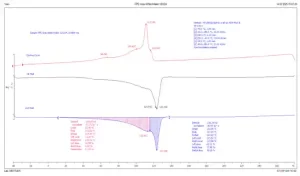

For example, consider the evaluation of a potato chip bag. The team at Flex-Pack would discover that the bag consists of two layers of polypropylene laminated together, with the first layer clear and reverse printed so you could see the packaging artwork. The second layer when you look inside appears shiny and would be metalized polypropylene and be a slightly different film which has excellent sealing properties. The reverse engineering process involves not only understanding the materials involved, but the special properties associated with each material. Flex-Pack would use a variety of analytical testing techniques such as infrared and DSC (differential calorimetry testing) and other tests to make the determinations of what the properties of the structures entail.

After these tests are completed we can understand very well, about 95%, of what that structure is comprised of as well as its unique properties and be able to tell our customers the details of the package: here’s what it is made of, here’s how it was put together, and here’s how we believe this can be assembled using your capabilities.

Why Reverse Engineering?

One of the most common reasons that companies want to do competitive analysis and reverse engineer structures is when they don’t currently participate in a particular industry or market segment. If they are making film and selling to converters who are making various types of flexible packaging products such as potato chip bags, frozen meat ball bags, etc., they may want to participate in that industry, but don’t know what is required. So, they have two choices: they can send their sales teams out to talk to potential customers to investigate what the specifications are and if there is an opportunity to work together. Or they can pull a package off the shelf and reverse engineer that structure to understand what is involved in that package, what materials make up that product, and if they currently have the capabilities with their current materials, equipment, and facility to make a similar package. Reverse engineering is easier, faster, and less expensive.

Why Flex-Pack Engineering for Reverse Engineering Services?

Flex-Pack Engineering is your ideal partner for reverse engineering services in the flexible packaging industry. We bring our long history (of 30 years of experience) to packaging analysis and evaluation. We not only provide you results, but we also provide insights and recommendations on what the results mean and how to improve or upgrade your current capabilities to be able to participate in additional industries and market segments.

Let’s have a conversation! Contact us today at 330-704-9436 or fill out our request information form and learn how Flex-Pack Engineering can help with your reverse engineering initiatives!