Plastic Compounding by Flex-Pack Engineering

Solving Tough Plastic Compounding Challenges

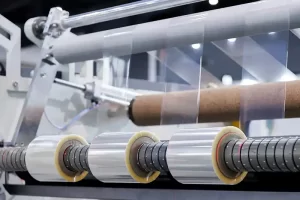

At Flex-Pack Engineering we enjoy taking on the toughest toll, custom and specialty plastic compounding challenges. Through careful analysis of the fitness for use (FFU) and chain of use (COU) and understanding of the performance expectations for your compounded product, we can select the best raw materials, engineer the best performing screw designs, and develop the process and manufacturing control plans to ensure a smooth running and high performing result.

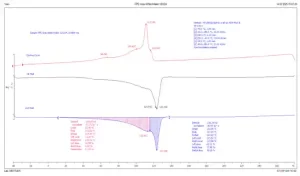

For example, consider a challenging application of compounding a very high viscosity, polyethylene – which is extremely difficult to compound on its own and you also have the need to include a difficult functional filler, such as clays, glass, or nanoparticles into the mix. It takes a significant amount of torque, requires a special screw design, and a great deal of expertise in process understanding to achieve a winning result. This type of technical challenge is at the center of our wheelhouse at Flex-Pack Engineering. We can analyze, design, and put in place a plan to produce the best results for these types of technically challenging plastic compounding applications.

Once the ideal design and process are created and proven we then select the best plastic compounding line on which to run on from our network of solid, reliable, and consistent contract/toll plastic compounding partners who share our philosophy of taking on the toughest plastic compounding jobs and who can produce high quality compound quickly and cost effectively.

Additionally, when working with Flex-Pack Engineering for your custom plastic compounding needs you have our entire team as your partner throughout the process. Since we selected the materials and engineered the screw designs and processes, we understand what can go right and what can go wrong and are in the perfect position to troubleshoot any issues that may occur in the plastic compounding process. We work synergistically between production and customer as a very well informed and educated bridge throughout the business relationship.

Flex-Pack Engineering: An Ideal Partner for Plastic Compounding

In our 30+ years of experience we have worked with customers who have had a wide array of technical challenges related to plastic compounding, or who needed short runs for proof of concept. We can accept smaller jobs and are an ideal choice to get plastic compounding projects done quickly. By applying sound science and engineering principles to solve the toughest plastic compounding challenges as well as provide overall flexible packaging solutions, we help our customers overcome those challenges and make a great product that can help win new business. And we can get it done quickly!

Ready to have a conversation? Contact us today at 330-704-9436 or fill out our request information form and learn how Flex-Pack Engineering can help with your difficult custom plastic compounding challenges!