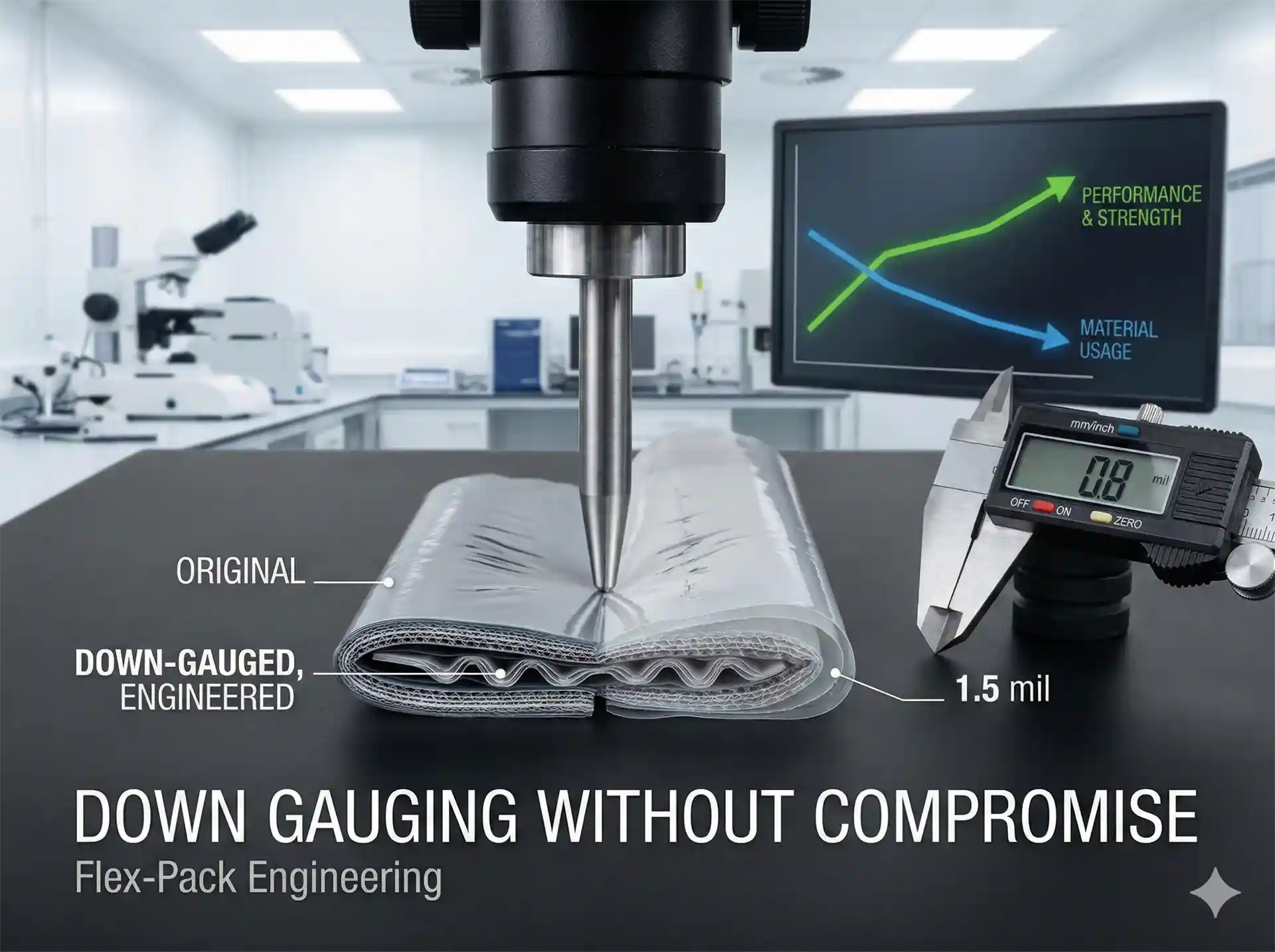

Down Gauging without Compromise

How to reduce material usage (and cost) through advanced product analysis and testing without losing puncture resistance or barrier protection.

In the modern packaging landscape, reducing material usage is a primary goal for both cost management and sustainability. However, “down gauging” is more than just making a film thinner; it is a technical process of reducing material weight through advanced product analysis and testing without sacrificing critical performance factors like puncture resistance or barrier protection.

Establishing the “Fitness for Use” Foundation

Successful down gauging begins with a comprehensive audit of your existing materials. It is not enough to simply reduce film thickness; you must first define the critical Fitness for Use (FFU) characteristics of your current film. This involves:

- Understanding Product Usage: Identifying how the product is used and which performance characteristics are essential to its success.

- Chain of Use Review: Performing an in-depth review of the product’s entire lifecycle and the specific stresses it encounters.

- Validation: Ensuring that any reformulated construction can still satisfy every FFU criteria before moving to production.

The Strategy: Formulation Over Thinning

To achieve a down gauged product that performs as well as (or better than) its predecessor, the construction or formulation of the film must often be changed.

While the goal is to use less material to lower costs, this process frequently involves adding higher-cost raw material components to compensate for the reduction in volume. Because of this complexity, the financial outcome can vary—sometimes there are immediate cost savings, and other times the costs remain neutral. The true value is often found in the long-term payback and improved material efficiency.

Managing Risk and Investment

Haphazardly changing production parameters carries significant risks. If a down gauging transition happens too quickly or in steps that are too large, the flexible packaging product may behave differently and fail in the field.

One of the greatest challenges in this process is educating stakeholders about the necessary steps and the associated costs of testing. There is an upfront investment required in analysis and reporting to realize a sustainable, long-term cost savings.

How FlexPack Engineering Can Help

Before making production changes, it is vital to have a partner who understands the relationship between film thickness and product performance.

FlexPack Engineering provides the professional analysis and reporting necessary to guide you through the down gauging process. We help you navigate the chain of use and FFU criteria to ensure your product remains protected while optimizing your material usage.

Contact FlexPack Engineering today at 330-704-9436 to begin your technical review.