What to Look for in a DSC Analysis Lab

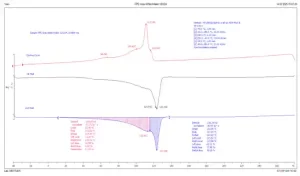

Differential Scanning Calorimetry (DSC) is a powerful thermal analysis technique used to measure how a material’s physical properties change as a function of temperature. It provides critical data on properties like melting temperature (Tm), glass transition temperature (Tg), crystallization temperature (Tc), and purity.

This analysis is vital for quality control, polymer characterization, product development, and competitive reverse engineering. However, the quality of these insights depends entirely on the laboratory you choose. Here’s what to look for in a DSC analysis lab.

- Deep Expertise and Industry Experience

A lab’s experience is paramount. Look for a team with decades of relevant experience, not just in running the equipment, but in your specific industry, such as flexible packaging, polymers, or pharmaceuticals. An experienced lab like FlexPack Engineering won’t just run a test; they will understand why you are running it. They should know how to use DSC testing to get the specific information you need, whether it’s to solve a production problem, conduct a competitive analysis, or assist in product development.

- State-of-the-Art Equipment and Calibration

The quality of the data is directly tied to the quality of the equipment. Ask potential labs if they have invested in cutting-edge DSC testing equipment (like FlexPack Engineering has), which provides more reliable and sensitive results.

Even more important is calibration. To ensure accuracy, all testing equipment must be meticulously calibrated to traceable standards, such as those from the National Institute of Standards and Technology (NIST). The lab should also be able to confirm that their equipment is verified and working properly before your test begins.

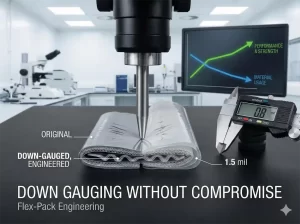

- Actionable Insights, Not Just Raw Data

A significant differentiator for a top-tier lab is its ability to provide interpretation, not just a graph. The most valuable labs are those that go beyond providing mere test results. Look for a partner such as FlexPack Engineering that offers critical insights and recommendations based on their findings. Their extensive background in materials and process development allows them to help you understand how to improve a packaging design, optimize a production line, or identify the root cause of a material failure.

- Use of Complementary Analytical Techniques

DSC is a powerful tool, but it often works best in conjunction with other methods. A well-equipped lab will often use DSC as part of a comprehensive analysis. For example, using it with FTIR (Fourier Transform Infrared Spectroscopy) helps to identify the complete chemical composition of an organic material. A lab that also offers other thermal analysis techniques, can provide a much more complete picture of your material’s behavior. At FlexPack Engineering we provide a wide variety of testing services for the flexible packaging industry.

- Clear Applications and Capabilities

The lab should be able to clearly articulate how they will use DSC to meet your specific goals. A good lab will have experience in a wide variety of applications, including:

- Polymer Characterization: Determining glass transition (Tg), melting, and crystallization temperatures.

- Quality Control: Measuring the purity of materials and identifying potential contaminants.

- Process Development: Understanding the kinetics of chemical reactions or curing processes.

- Material Identification: Measuring the crystalline content of a polymer to be used as a reference.

- Reliability, Turnaround, and Service

Finally, consider the practical aspects of working with the lab. Inquire about their standard turnaround times and whether they can meet your project deadlines. A lab that offers fast, reliable results, competitive pricing, and friendly, accessible customer service will be a much better long-term partner for all your flexible packaging and material analysis needs.

FlexPack Engineering: Providing Fast and Reliable DSC Testing and Analysis

At Flex-Pack Engineering we bring over 30 years of experience in our flexible packaging analysis and evaluation, and DSC testing is an important tool that we use in our workflow. We know how to use DSC testing to get the information our customers need to improve their packaging products.

Furthermore, we have invested in state-of-the-art DSC testing equipment to provide reliable results with better than industry standard turnaround times. All our testing equipment is calibrated to NIST traceable standards and verified to be working properly before testing begins.

While having the knowledge and equipment necessary to provide DSC testing is important, what benefits our customers the most is Flex-Pack’s extensive background and experience in flexible packaging product and process development. We not only provide you test results, but critical insights and recommendations on how to improve your packaging design, or production line operations. We offer very competitive pricing with exceptional turnaround time and friendly customer service to help you with all your flexible packaging requirements.

Let’s have a conversation! Contact us today at 330-704-9436 or fill out our request information form and learn how Flex-Pack Engineering can help with your DSC testing requirements today!